About half a year ago, I made a project of AQI device with Raspberry Pi Pico W and ENS160+AHT21 chips. I put them on a block of 2X4 wood. Now I have a chance to make a box with my 3D printer. I can also design it on Autodesk Fusion with my limited 3D design experience.

I started the design on the paper first.

I started the design on the paper first.

Then transfer it to the Fusion software.

Then transfer it to the Fusion software.

I exported it to the 3mf format. Loaded it to the Bambu Studio. Sliced and printed it.

I exported it to the 3mf format. Loaded it to the Bambu Studio. Sliced and printed it.

OK, I put the heat inserts for the screws.

OK, I put the heat inserts for the screws.

I need iron to heat the bronze inserts and push them into the hole. It doesn’t need much push.

I need iron to heat the bronze inserts and push them into the hole. It doesn’t need much push.

I re-soldered the wires. I replaced the old wires with soft, flexible wires. Add the cover.

I re-soldered the wires. I replaced the old wires with soft, flexible wires. Add the cover.

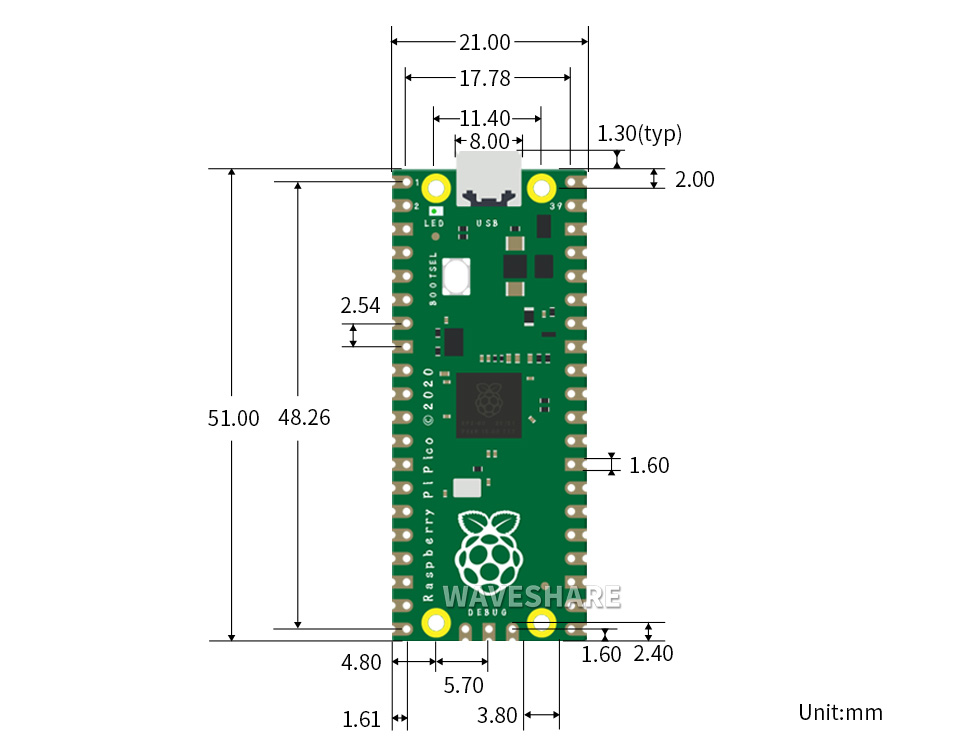

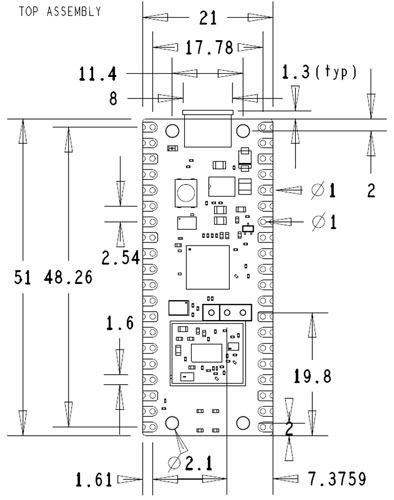

The only problem of the design is the distance of the four holes of Pico is not that correct. I am not sure if it is the measurement issue or the printer issue.

The only problem of the design is the distance of the four holes of Pico is not that correct. I am not sure if it is the measurement issue or the printer issue.

But, it is not the problem. I can use two screws for the Pico. One screw for the ENS160 and AHT21 board.

Update: Just found the problem, I used the Pico size instead of Pico W. So there is a little bit of difference.

Here is the web report page.

The 3mf and f3d files can be located at MakeWorld website:

AQI container for Pico W and ENS160+AHT21